- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

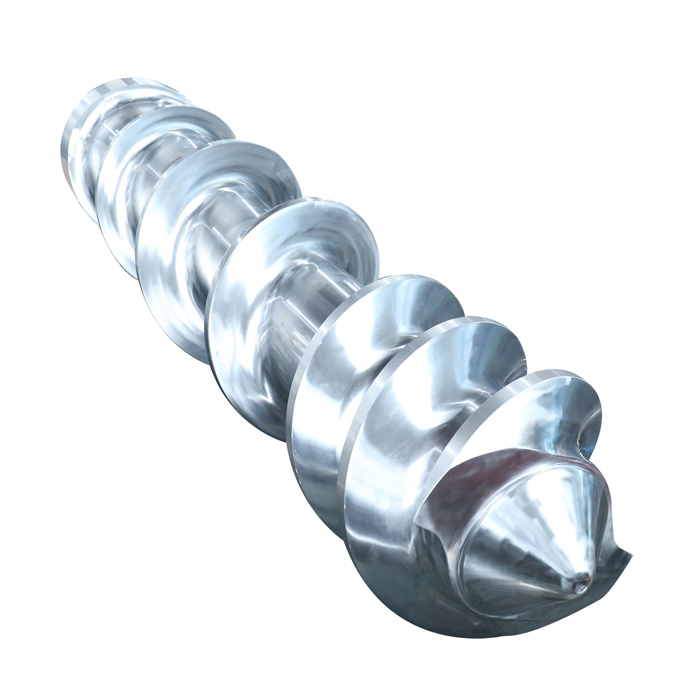

Hot Feed Rubber Extrusion Screw And Barrel

Rubber industry only had Hot Feed Extruders until 1950’s. Hot Feed Extruders(HFE) extrude rubber compounds at reduced temperatures. EJS produces hot feed rubber extrusion screw and barrel, with rich experiences working with leading players in the rubber field in different countries.Welcome to buy Hot Feed Rubber Extrusion Screw And Barrel from us.

Send Inquiry

Hot Feed Rubber Extrusion Screw And Barrel

Sticking to your principle of "Making customer’s screw barrel business Easier with Joys and Success" , we are striving to get a fantastic business partner for you for China Manufacturers Hot Feed Rubber Extrusion Screw And Barrel. Warmly welcome to join us, let's grow together for the better future.

Rubber industry only had Hot Feed Extruders until 1950’s.

Hot Feed Extruders(HFE) extrude rubber compounds at reduced temperatures.

EJS produces hot feed rubber extrusion screw and barrel, with rich experiences working with leading players in the rubber field in different countries.Every year, E.J.S exhibits our screw barrels at different shows. We meet our old and new customers at npe show.

Bore diameter available for Hot feed rubber extrusion screw and barrel

40 ~ 250mm

L/D ratio for Hot feed rubber extrusion screw and barrel

Varies from 4: 1 to 6: 1

Surface Treatment of Hot feed rubber extrusion screw and barrel

Nitrided

Hard Chrome Plating

Ceramic coated

Hardfacing / Bimetallic with Ni60, Colmonoy 56, Colmonoy 83

Quenching

Material request for Hot feed rubber extrusion screw and barrel

The material for rubber screw must be:

Anti-high temperature;

Anti-wearing;

Anti-corrosion;

High strength to work with high torque and high speed;

Good cutting performance;

The relief and the thermal deformation is small after heat treatment.

The material for rubber barrel include:

38CrMoAlA (DIN1.8509)

42CrMo ( AISI4140)

Stainless steel 304

Application of Hot Feed Rubber Extrusion Screw And Barrel

Tread, Tubes, Profiles, Hoses, Sheeting with Roller die head, Cable coating, Dock Fenders, Straining of Raw materials, Press blanks, pre-warming for Calendar feeding, Inner tubes for Bicycle, cars and Trucks etc.

About E.J.S.

EJS Screw Barrels is a newly created brand name for Export business with manufacturing experiences since 1992.

A screw barrel manufacturer dedicated on producing customized screw barrel and design extruder screw barrels, injection moulding screw barrels.

Bimetallic Screw Barrels

We started to make bimetallic screw barrel at a very early age, almost the same time as the first bimetallic barrel was born in China. Now we have several types for options depending on different applications

|

Bimetallic Barrels |

|||||

|

Alloy Type |

EJS01 Alloy |

EJS02 Alloy |

EJS03 Alloy |

EJS04 Alloy |

|

|

Alloy Components |

Fe+Ni+Cr+B |

Ni+Cr+Co+B |

Ni+Cr+Co+V+B |

Ni+Wc+Cr+B |

|

|

Wearing Resistance |

★★★ |

★★ |

★★★ |

★★★★ |

|

|

Corrosion Resistance |

★★ |

★★★ |

★★★ |

★★★ |

|

|

Alloy Thickness |

2~3mm |

1.5~2mm |

1.5~2mm |

1.5~2mm |

|

|

Hardness |

HRC 58-65 |

HRC 50-58 |

HRC 55-60 |

HRC 55-65 |

|

|

Temperature Range |

≤400 |

≤450 |

≤450 |

≤600 |

|

|

Coefficient Thermal |

RT~250℃ |

11.0x10-6 |

11.0x10-6 |

11.5x10-6 |

11.0x10-6 |

|

Expansion(/℃) |

RT~400℃ |

11.4x10-6 |

11.4x10-6 |

12.4x10-6 |

12x10-6 |

|

Range of Workable Length |

700mm~3000mm/piece |

||||

|

Base Steel Vastly Used |

40Cr: 42CrMo |

||||

|

Mark in the list: ★★★★ Excellent; ★★★ Very Good; ★★Good |

|||||

|

Bimetallic Screws |

|||

|

Suitable for |

Single Screw, Twin Parallel Screw, Twin Conical Screw |

||

|

Alloy Type |

Ni60 |

CoImonoy 56 |

CoImonoy 83 |

|

Alloy Components |

Ni+Cr+Fe+Si |

Ni+Cr+Si+Fe |

Ni+Wc+Cr+C |

|

Anti-Wearing Level |

★★★ |

★★★ |

★★★★ |

|

Anti-Corrosion Level |

★★★★ |

★★★★ |

★★★★ |

|

Alloy Thickness |

1~1.5mm |

1~1.5mm |

1~1.5mm |

|

Hardness |

HRC 56-62 |

HRC 46~61 |

HRC 43-48 |

|

Applied Glass Fiber |

Under 10% |

|

|

|

Range of Workable Length |

Any length needed |

||

|

Base Steel Vastly Used |

38CrMoAI(1.8509), 34CrAINi7(1.8550), 31CrMoV9(1.8519) |

||

|

Mark in the list: ★★★★ Excellent; ★★★ Very Good; ★★Good |

|||

Quality Inspection

Quality is a very important step during production. For making a quality screw barrel, all tolerances should be fulfilled and all dimensions should be correct and put in records.

We provide inspection report, material certificate for every of our supplied screw barrels.

Packaging

Packaging is the last but very important step before shipping. A strong and smart packing box is also part of our quality. It is not only used to protect the screws barrels well during transportation, also provide an easy way for our customer to unpack.